CNC Machining Write For Us

In 1952, the Massachusetts Institute of Technology and John C. Parsons developed the first CNC-operated machine. Basically, it was accomplished with bulbs, a binary code, and a perforation tape. And also, it is a hybrid between the electro-mechanical component of the machine tools used in machining by turning but automatic. However, all these are thanks to a computer operating system that directs each function and minimizes human intervention. In addition, greater productivity is gained in less time and with high precision.

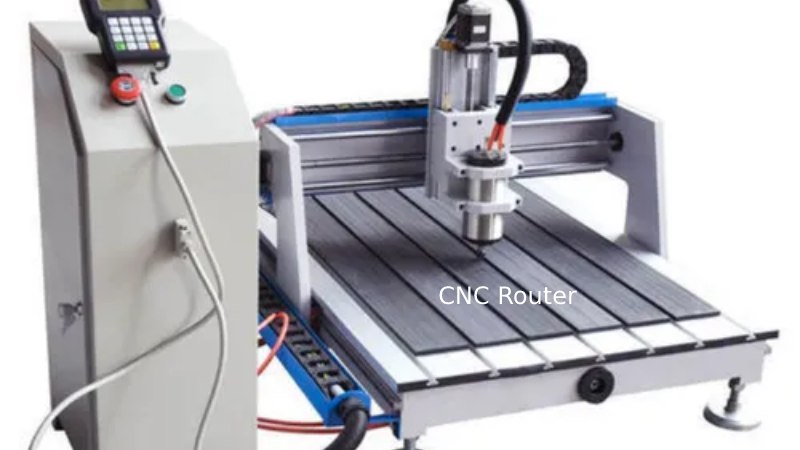

Basically, a CNC router is used to produce objects such as door carvings, interior & exterior decorations, wood panels, signs, wood frames, mouldings, musical instruments, and furniture. Additionally, they see use in industry in thermoforming plastics by automating the trimming process. And also, CNC routers can help ensure partial redundancy and sufficiently efficient performance for production or allow for unique designs.

In short, CNC machining is an automated machine tool controlled by a computer. And also, using spinning tools with multiple cutting edges and very little human intervention can carry out different operations on a piece. But also, turning, milling, drilling, and even complementing all of them in a single machine. However, this type of machining has been applied in multiple roughing or chip removal operations.

Applications and Advantages of CNC Machining

We already mentioned some benefits of CNC machining, such as introducing programs in machining processes. It makes parts with high complexity in their design challenging to be a machine in conventional machine tools. However, this advance has achieved the development of components for various industries. Moreover, some are aerospace, naval, rail, and aeronautics. All in all, the CNC machining applied routers that allow the cutting of materials using water pressure, laser, or plasma.

Additionally, it offers a considerable improvement in precision, reducing errors and improving productivity. And by drastically reducing human intervention, the risk of workplace accidents is lower. And also, it is worth noting the cost savings since it reduces metal waste. Moreover, it has automatic chip removal, cleaning, reuse, and recycling. And even CNC machinery can perform complex jobs just by setting up the machine and integrating the programs.

How to Submit Your Articles?

All in all, You can email us at contact@technologycompanians.com to Write For Us.

Why to Write for Technology Companians Site – CNC Machining Write for Us

Writing for Technologycompanians can give massive exposure to your website for customers looking for CNC Machining.

Technologycompanians presence is on Social media and will share your article for the CNC Machining. related audience.

You can reach out to CNC Machining enthusiasts.

Search Terms Related to CNC Machining Write for Us

Automated Control

Machining

Drills

Lathes

Mills

3D printers

Computer

G-Code

CAD – Computer-Aided Design

CAM – Computer-Aided Manufacturing

Handwheels

PostProcessor

Stepper Motors

Servo Motors

Open-loop control

Metalworking

Repeatability

Laser cutting

Welding

Friction Stir Welding

Ultrasonic Welding

Flame

Plasma Cutting

Bending

Spinning

Hole-Punching

Search Terms for CNC Machining Write for Us

CNC Machining Write for us

Guest Post CNC Machining

Contribute CNC Machining

CNC Machining Submit post

Submit an article

Become a guest blogger CNC Machining

CNC Machining writers wanted

suggest a post CNC Machining

CNC Machining guest author

Guidelines of the Article – CNC Machining Write for Us

We at Technologycompanians welcomes fresh and unique content related to CNC Machining.

Technologycompanians allow a minimum of 500+ words related to CNC Machining.

The editorial team of Technologycompanians does not encourage promotional content related to CNC Machining.

For publishing article at Technologycompanians email us at contact@technologycompanians.com

Technologycompanians allows articles related to gadgets, software, apps, tech and many more.

Related Pages

3d Rendering Write For Us

Gaming Headphones Write For Us

PMP Write For Us

CSPO Write For Us

Electric Vehicles Write For Us